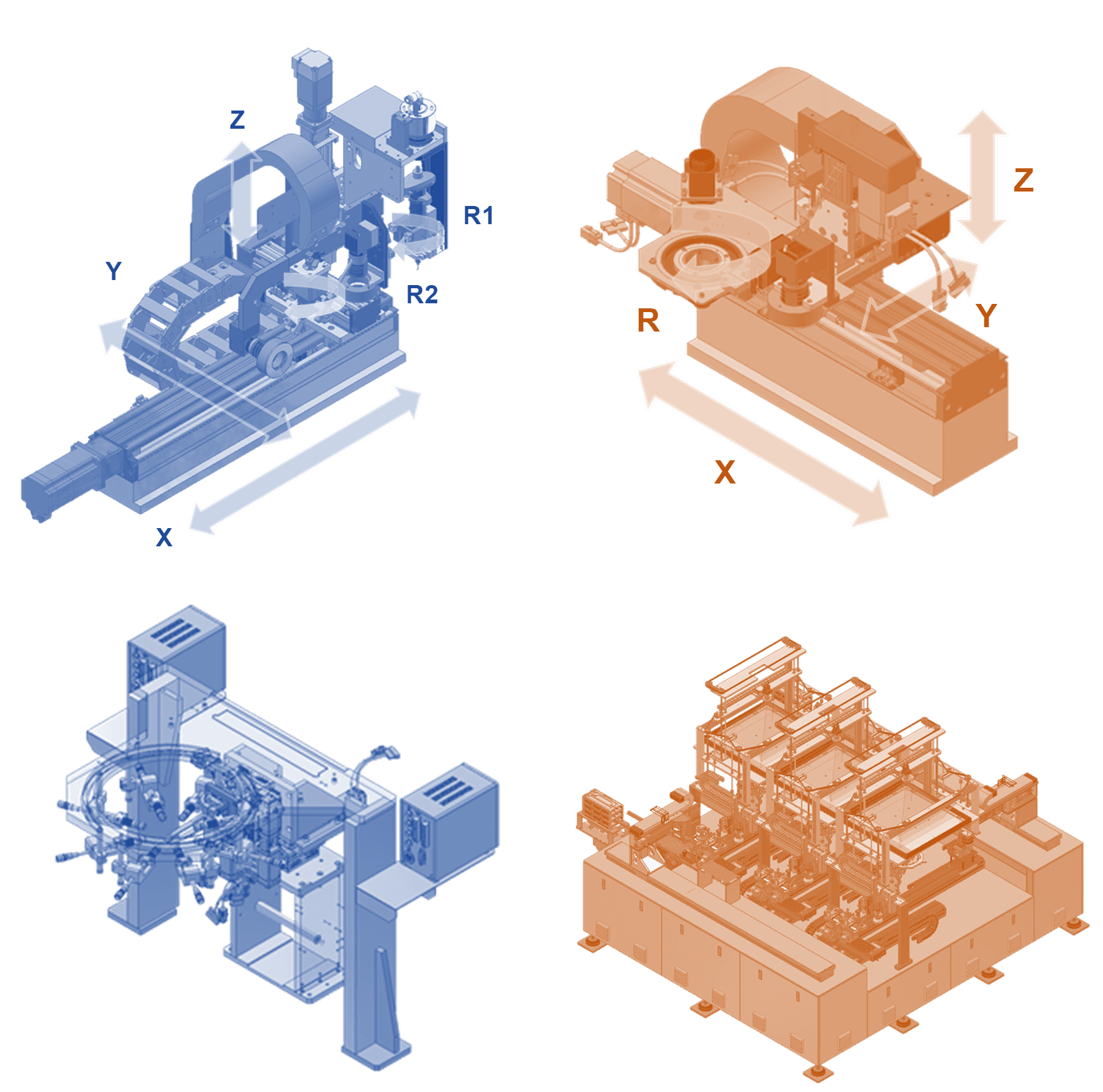

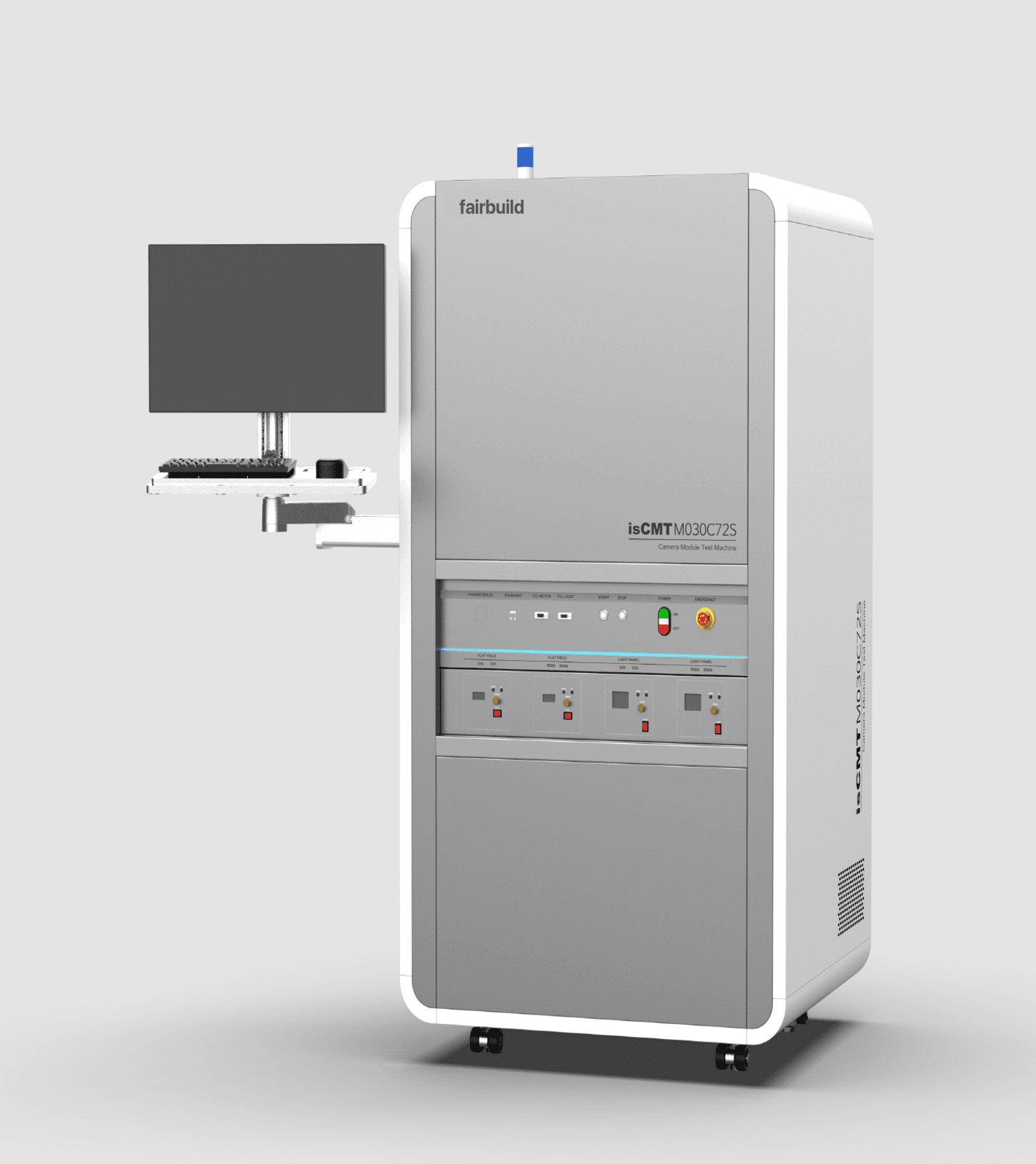

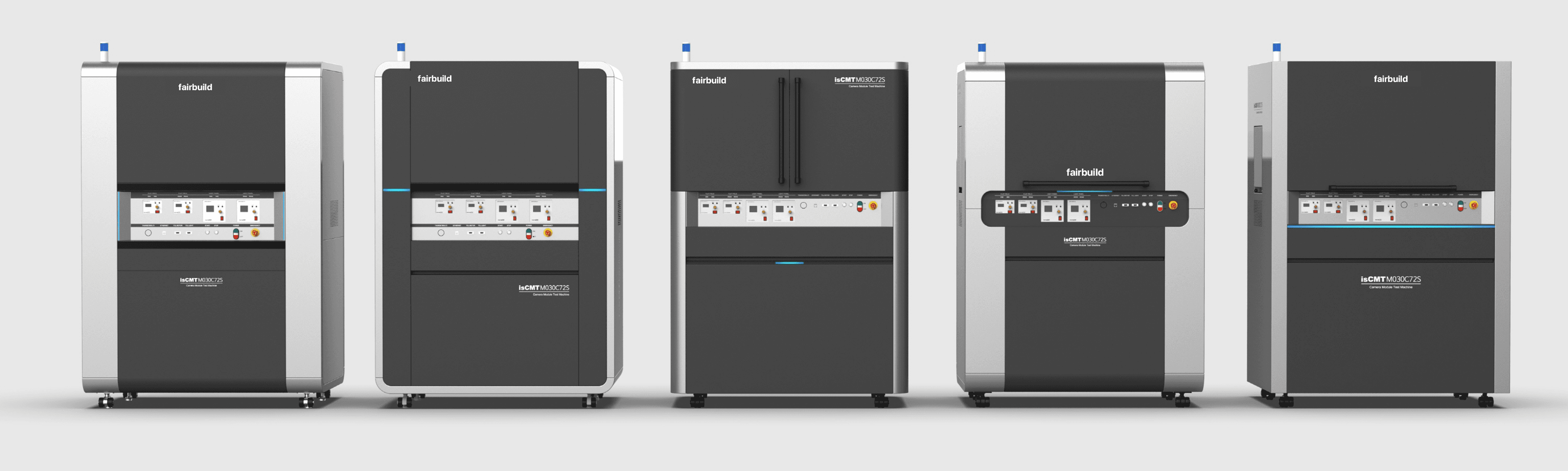

Customizable R&D Test Stations with Full Automation Support

At Fairbuild, we take pride in our ability to precisely understand and address your metrology test requirements. Our state-of-the-art R&D test stations support a wide range of configurations for comprehensive test coverage, and feature a robust Python API that enables full automation of motion control, instrumentation, file I/O, and data processing—empowering teams to prototype, validate, and iterate with efficiency and accuracy.

Intuitive Design and Easy Maintenance

Transparent Pricing

Python Programming for Core Tester Functions

Test Sequence Design with Python Scripting

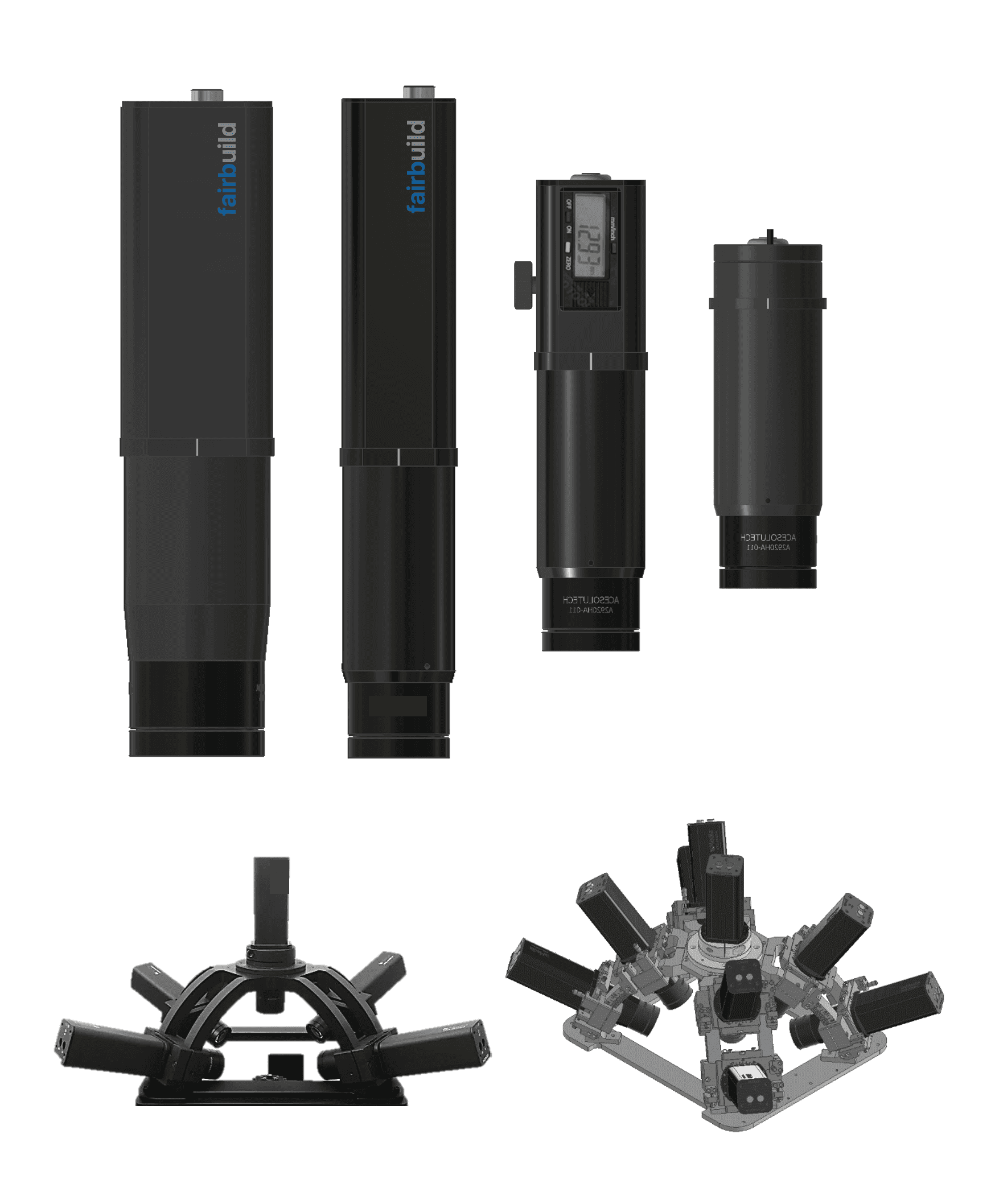

High-Precision SFR Target Projection for Sharpness Evaluation

Fairbuild employs state-of-the-art SFR target projectors and rigorous quality control procedures to evaluate image sharpness in mission-critical camera systems, particularly where target distances of 1.0 meter or greater are required. Our projectors are engineered to meet stringent safety and performance standards, making them ideally suited for vision systems in driver-assist and autonomous driving applications.

Industrial Application MIPI 2.0 Gbps Frame Grabbers

The Fairbuild C-phy and D-phy MIPI frame grabber is an ideal solution for camera testing, supporting a broad range of image sensor resolutions up to 268 MP. With Thunderbolt 3.0 compatibility, our frame grabber can be easily connected in a daisy-chain configuration, making it perfect for test stations that require multiple frame grabbers and clean wire management. Our frame grabbers are specifically designed for factory operations that require nonstop 24/7 operation, ensuring reliable and consistent performance.

Licensable Software Assets

and Design Libraries

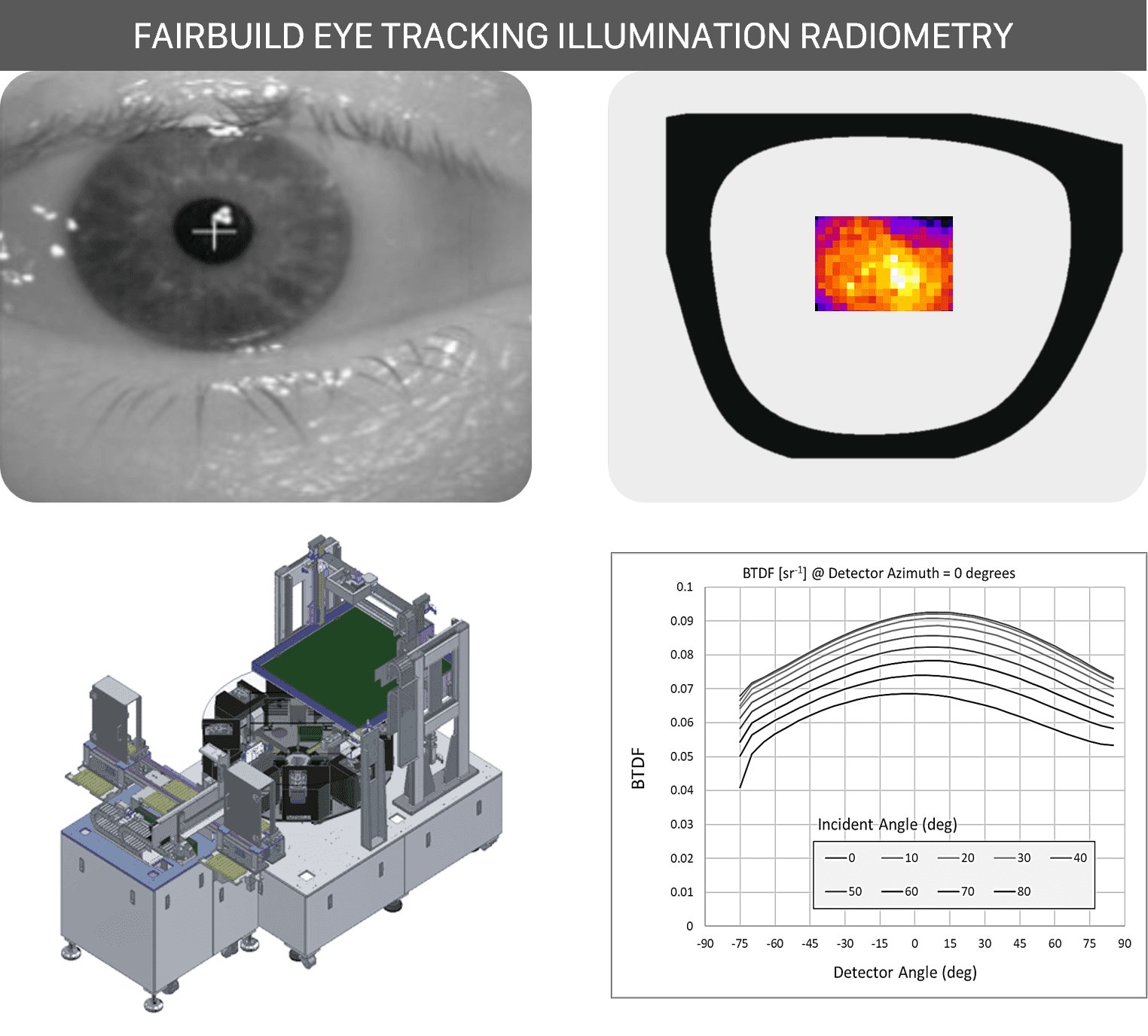

Ensuring Integrity in Eye-Tracking VCSEL/LED Manufacturing

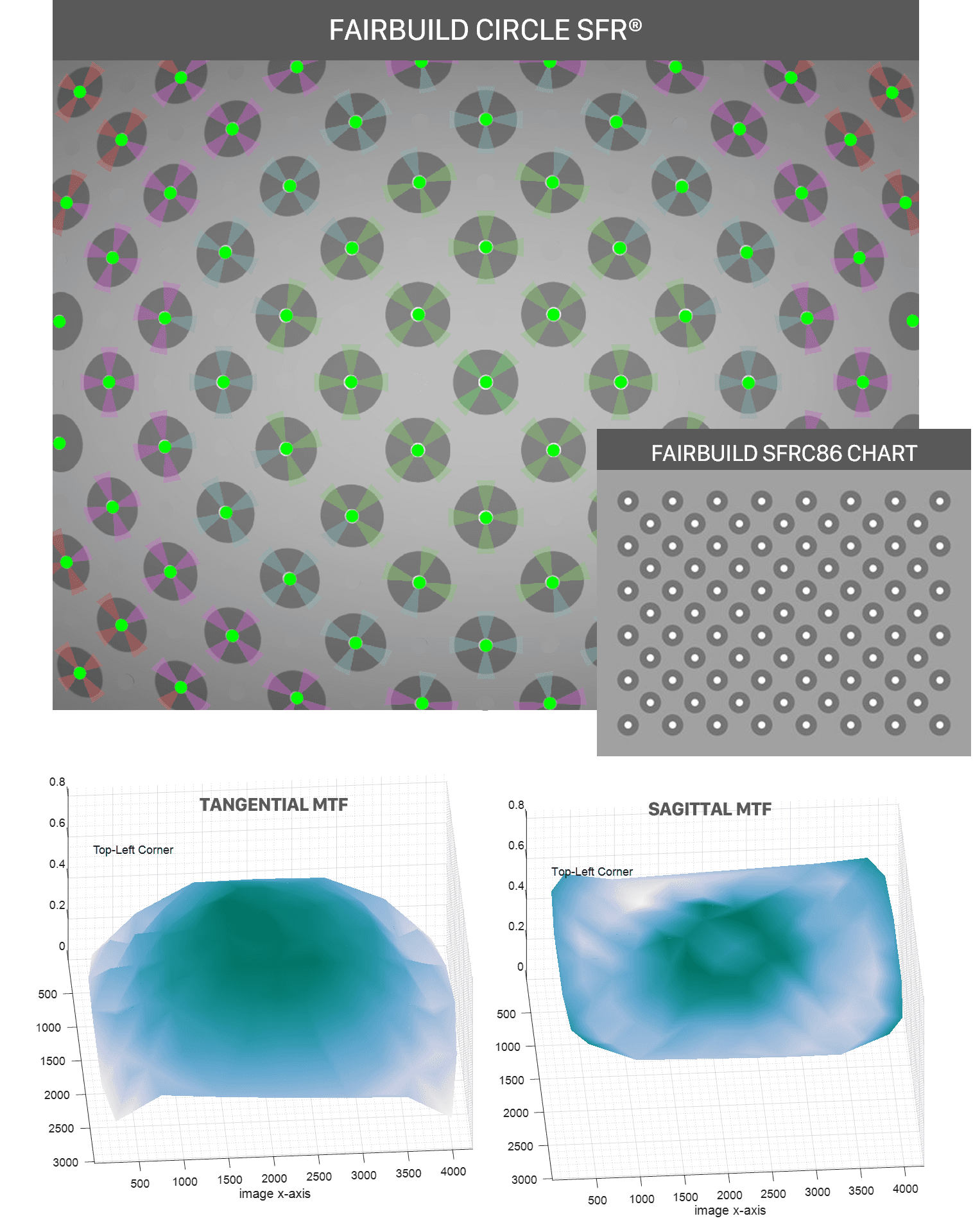

Fairbuild’s Circle SFR® enables precise comparison of sagittal and tangential spatial frequency response (SFR) measurements against optical simulation results—offering deep insight into lens and camera assembly quality. Deviations or tilt in the measured MTF surfaces may reveal potential misalignment between the lens and image sensor, allowing early detection of build issues.

For camera and display manufacturers, we offer licensing of the Circle SFR® production binary, built to deliver fast, reliable, and simulation-aligned optical analysis on the factory floor. Having undergone multiple refinements in high-volume environments, Circle SFR® is optimized for robustness, throughput, and real-time execution in demanding production settings.

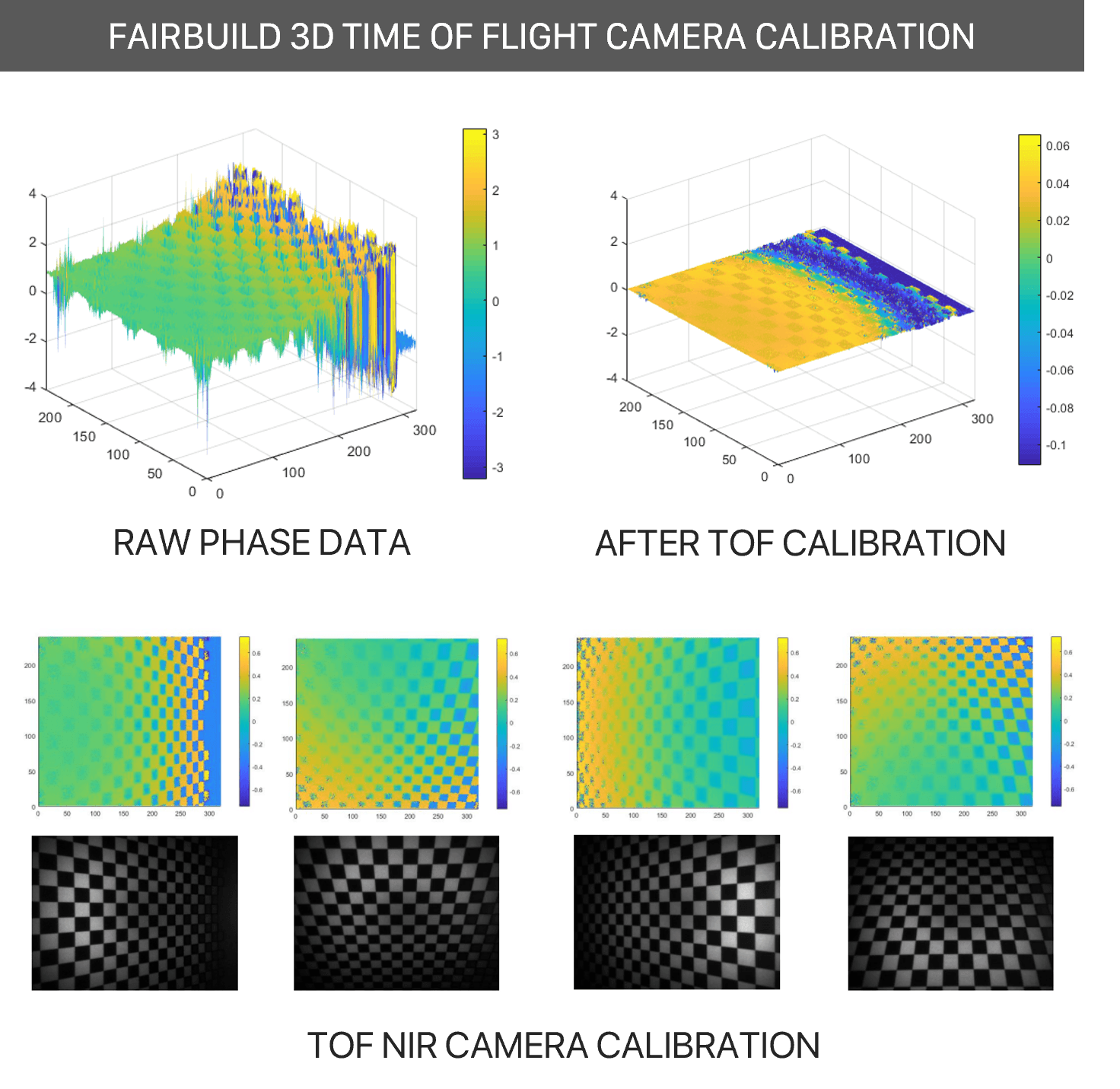

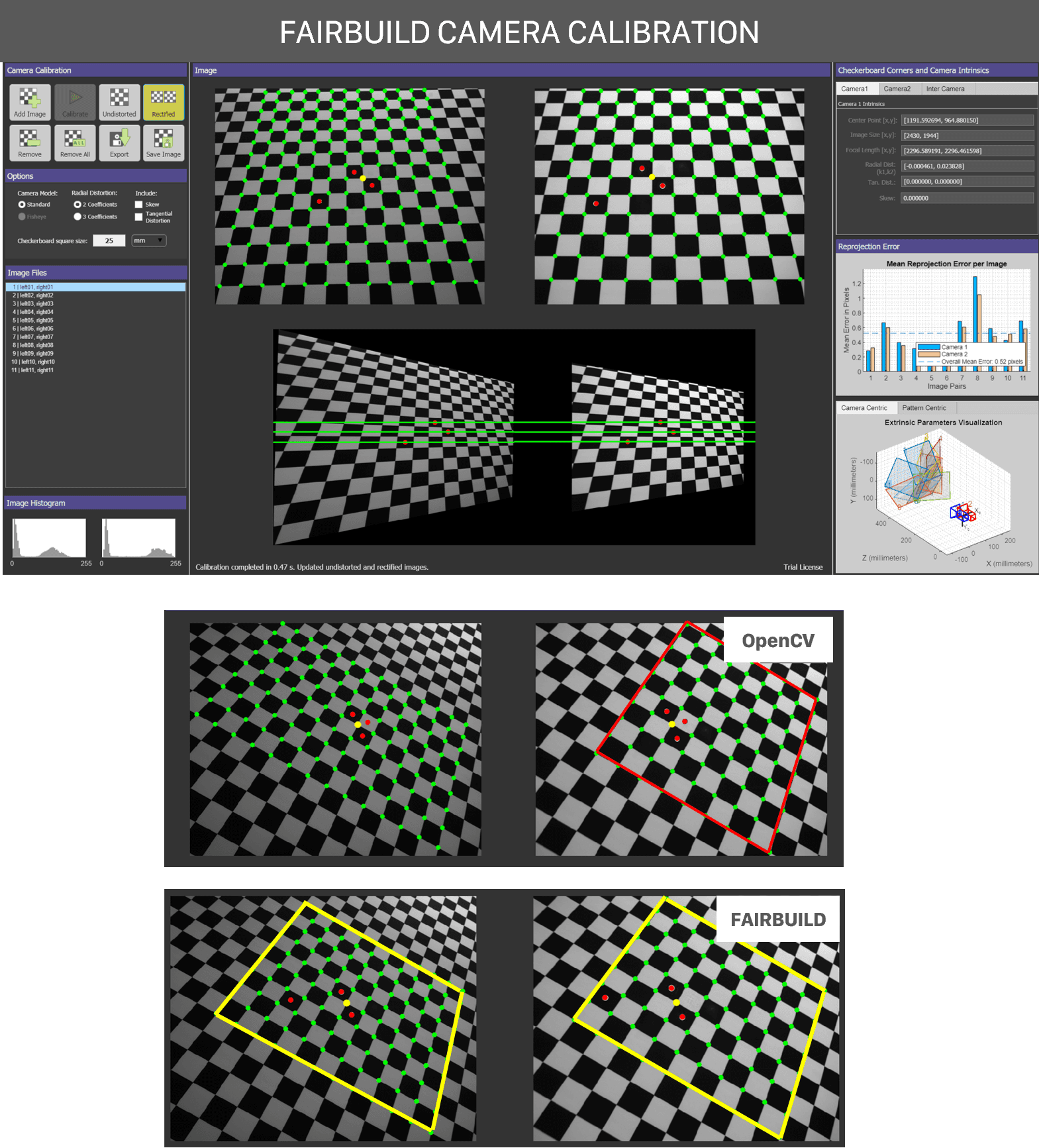

High-Precision Camera Calibration for Scalable Manufacturing

Have a project? let’s connect

Send us a note to reach out to our experienced staff.